RepRap: in simple terms, part 1: replication.

What does the RepRap project do? What do they mean with self-replication?

Its aim is to design, through the open source process, a 3D printer that can replicate most of its own parts. Currently a large fraction of the parts can in fact be 3D printed, save some nuts and bolts and rods (60+ unique parts, little over a hundred of parts in total are printed). This fraction won’t increase much because it’s already reached a point where fabbing (fabricating) the supporting rods is not desirable (total costs are very low, they are available anywhere), but it could be done nevertheless. Same goes for screws and such.

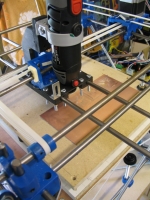

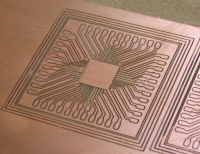

What is still desirable to be able to replicate is the electronics. In fact, the standard (1.0) model of the RepRap, the ‘Darwin’ is capable of milling professional-looking and absolutely functional PCBs for the electronics:

Some initial successes are in fabricating the stepper motors to control the motion of the machine. The need for fabricating readily available stepper motors, that can even be scavenged from dead/outdated 2D printers is not that pressing to fuel this avenue of development, but it certainly is possible that we will 3D print the basis for functional motors.

Why is it important to 3D print specialist parts and not (as much) nuts and bolts?

Because the custom parts that convey most of the thinking need to be reproduced faithfully. More practically, those parts are impossible to acquire otherwise (you cannot find them in traditional stores like with nuts and bolts).

Isn’t there a chicken and egg problem that you need at least one RepRap to make more of them?

There is. But fortunately, to mitigate the problem in a world where there no RepRap in every major city (YET!), there are “RepStraps”. Those are 3D printers that can be made from various parts and through various techniques. The result can then print a RepRap. Many rapid prototyping machines, can produce parts for a RepRap (there are arcylic, steel, plywood and FDM versions of most parts). In the Netherlands, for example, there are four public FabLabs: Amsterdam (Waag), Utrecht (Protospace), The Hague and Texel. Both Eindhoven and Tilburg are just starting-up a new FabLab. Finally, a FabLab 2,6 kilometers away (1.6 miles)!! I’ll be working with Protospace to help make a couple of RepRaps there. The first ones will probably be laser-cut acrylic RepRaps, since they can easily be made on their existing equipment. After that, they can print mechanically strong and durable 3D parts with this first RepRap.

RepRap can also function as a bootstrap machine to 3D print parts for other machines than itself. RepRap is more than just the machine, it is also the toolchain in software. Most of all, it is the helpful an very thriving, knowledgeable multi-disciplinary community.

For more information, check out these websites:

Recente reacties